-

NHX

◆Low ESR, large capacity in a compact package, high ripple current, and high reliability ◆105°C, guaranteed for 2000-5000 hours ◆AEC-Q200 compliant RoHS compliant

-

VPW

Ultra-long life, low ESR,

high ripple current resistance,

high current shock resistance,

long-term high temperature stability

-

CW3S

Aluminum Electrolytic Capacitor

Snap-in Type

Ultra-small size, high reliability, ultra-low temperature 105°C, 3000 hours, suitable for industrial drives, servo RoHS directives

-

SW6

Aluminum Electrolytic Capacitor

Snap-in Type

High ripple, long life, high temperature resistance 105°C 6000 hours, suitable for frequency conversion, servo, power supply RoHS directive

-

VHR

Conductive Polymer Hybrid Aluminum Electrolytic Capacitors

SMD Type♦ Low ESR, small size, high allowable ripple current and high reliability

♦ Guaranteed for 2000 hours at 105℃

♦ Can meet vibration resistance requirements

♦ Surface mount type high temperature lead-free reflow soldering

♦ The product complies with AEC-Q200 and has responded to the RoHS directive -

NHM(Suspension of sales)

Conductive Polymer Hybrid Aluminum Electrolytic Capacitors

Radial Lead Type

Low ESR, high allowable ripple current, high reliability, 125℃ 4000 hours guarantee,

compliant with AEC-Q200, already compliant with RoHS directive.

-

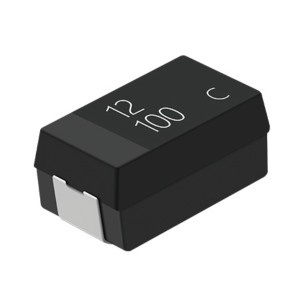

TPD40(Sales suspended)

Conductive Tatanlum capacitor

Large capacity product (L7.3xW4.3xH4.0),Low ESR,

high ripple current,High voltage products (100V max.),RoHS Directive (2011 /65/EU) Compliant

-

-300x300.png)

SLA(H)

◆ Hybrid supercapacitor (LIC), 3.8V, 1000-hour lifespan, automotive-grade hybrid supercapacitor

◆ Excellent temperature characteristics: Chargeable at -40℃, dischargeable at +90℃, applicable temperature range: -40℃ to +90℃

◆ High current operating capability: Continuous charging 20C, continuous discharging 30C, instantaneous discharging 50C

◆ Ultra-low self-discharge characteristics, 10 times the capacitance of double-layer capacitors of the same volume

◆ Safety: Safe materials, non-explosive, non-flammable, compliant with AEC-Q200, RoHS, and REACH

-

SLD

◆ Hybrid Supercapacitor (LIC), 4.2V High Voltage Product

◆ High Energy Density Product: Rechargeable at -20℃, dischargeable at +70℃, applicable temperature range: -20℃ to +70℃

◆ Ultra-low self-discharge characteristics, with a capacitance 15 times that of double-layer capacitors of the same volume

◆ Safety: Safe materials, non-explosive, non-flammable, compliant with RoHS and REACH directives

-

CW3

Aluminum Electrolytic Capacitor

Snap-in Type

Small volume ultra-low temperature 105°C ,3000 hours is suitable for household frequency conversion, servo RoHS directive correspondence

YMIN CW3 series aluminum electrolytic capacitors, with their ultra-low temperature adaptability, long life of 3000 hours, low ESR/DF, high ripple current carrying capacity, and some models complying with the automotive-grade AEC-Q200 standard, provide a solid guarantee for engineers to build high-performance and high-reliability power electronic systems in harsh environments.

-

LED

Aluminum ELectrolytic Capacitor

Radial Lead Type

High temperature resistance, long life, LED special product,2000 hours at 130℃,10000 hours at 105℃,Compliant with AEC-Q200 RoHS directive.

In today’s rapidly developing electronics industry, the reliability and performance of components are crucial. YMIN Electronics’ LED aluminum electrolytic capacitor series is designed for high-performance applications in harsh environments, especially in the lighting, industrial power supply, and automotive electronics fields.

-

-300x300.png)

MDP(X)

Metallized Polypropylene Film Capacitors

- DC-Link Capacitor for PCBs

Metalized polypropylene film construction

Mould-encapsulated, epoxy resin-filled (UL94V-0)

Excellent electrical performance

The MDP(X) series metallized polypropylene film capacitors, with their excellent electrical performance, high reliability, and long life, have become indispensable core components in modern power electronics systems.

Whether in renewable energy, industrial automation, automotive electronics, or high-end power supplies, these products provide stable and efficient DC-Link solutions, driving technological innovation and performance improvements across various industries.

- DC-Link Capacitor for PCBs