Main technical parameters

| Item |

characteristic |

||||||||

| Operating

temperature range |

-40~+105℃ | ||||||||

| Nominal voltage range | 400-500V | ||||||||

| Capacity tolerance | ±20% (25±2℃ 120Hz) | ||||||||

| Leakage current(uA) | 400-500WV I≤0.015CV+10(uA) C: Nominal capacity (uF) V: Rated voltage (V) 2 minutes reading | ||||||||

| Loss tangent

(25±2℃ 120Hz) |

rated Voltage(V) | 400 | 450 |

500 |

|||||

| tgδ | 0.15 | 0.18 |

0.20 |

||||||

| Temperature

characteristics (120Hz) |

rated Voltage(V) |

400 |

450 | 500 | |||||

| impedance ratio Z(-40℃)/Z(20℃) |

7 |

9 |

9 |

||||||

| Durability | In a 105℃ oven, apply the rated voltage including the rated ripple current for the specified time, then place it at room temperature for 16 hours and then test. The test temperature is 25±2℃. The performance of the capacitor should meet the following requirements. | ||||||||

| Capacity change rate | Within ±20% of initial value | ||||||||

| Loss tangent | Below 200% of the specified value | ||||||||

| Leakage Current | below the specified value | ||||||||

| Load life | ≤Φ 6.3 | 2000 Hrs | |||||||

| ≥Φ8 | 3000Hrs | ||||||||

| High temperature and humidity | After storage for 1000 hours at 105°C, test at room temperature for 16 hours. The test temperature is 25±2°C. The performance of the capacitor should meet the following requirements. | ||||||||

| Capacity change rate | Within ±20% of initial value | ||||||||

| Loss tangent | Below 200% of the specified value | ||||||||

| Leakage Current | Below 200% of the specified value | ||||||||

Product Dimensional Drawing

Dimension (unit:mm)

|

D |

5 |

6.3 |

8 |

10 |

12.5~13 |

14.5 | 16 | 18 |

|

d |

0.5 |

0.5 |

0.6 |

0.6 | 0.7 | 0.8 | 0.8 | 0.8 |

|

F |

2.0 |

2.5 |

3.5 |

5.0 | 5.0 | 7.5 | 7.5 | 7.5 |

|

a |

L<20 a=±1.0 L ≥20 a=±2.0 |

|||||||

Ripple Current Frequency Correction Coefficient

| Frequency(Hz) |

50 |

120 |

1K |

10K-50K |

100K |

|

coefficient |

0.40 |

0.50 |

0.80 |

0.90 |

1.00 |

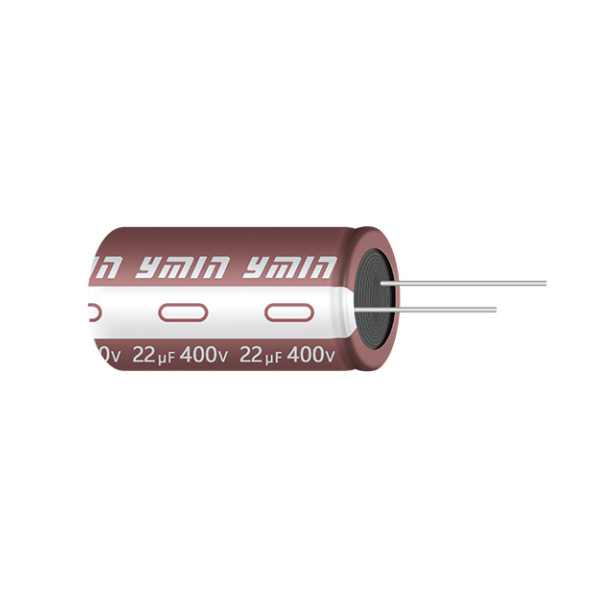

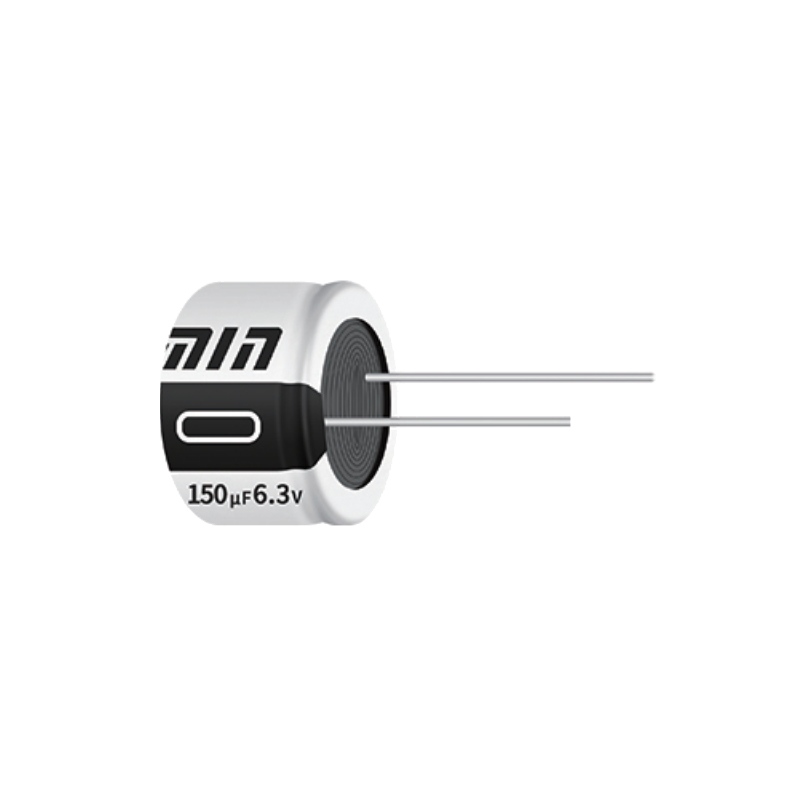

KCM Series Aluminum Electrolytic Capacitors: The "Energy Guardians" of High-Reliability Electronic Devices

In the modern electronics industry, the choice of capacitor often determines the stability and lifespan of the entire electronic system. YMIN's KCM series aluminum electrolytic capacitors, with their superior technical features and reliable performance, are becoming an ideal choice for demanding applications. This article will provide an in-depth analysis of the KCM series' technical features, application advantages, and practical application value.

Technical Features That Push the Limits

The most striking features of the KCM series aluminum electrolytic capacitors are their wide operating temperature range (-40°C to +105°C) and exceptional high-temperature durability. Even at 105°C, they can maintain stable operation for up to 3,000 hours, a remarkable feat among similar products. This high-temperature resistance makes the KCM series particularly suitable for electronic devices operating in high-temperature environments, such as control units in automotive engine compartments and industrial motor drive systems.

The series' rated voltage range is 400-500V, covering the needs of medium and high-voltage applications. The high rated voltage allows the KCM series to withstand higher voltage stresses, excelling in applications such as power supply filtering and energy buffering. Furthermore, the product utilizes specialized materials and process design to ensure lightning surge resistance, a feature particularly important in applications susceptible to lightning strikes, such as outdoor electronic equipment and communication base stations.

In terms of electrical performance, the KCM series exhibits low leakage current and low impedance at high frequencies. Low leakage current effectively reduces the system's static power consumption. Low ESR (equivalent series resistance) ensures the capacitor maintains excellent performance even in high-frequency environments, which is crucial for high-frequency applications such as switching power supplies.

Carefully Designed Structural Advantages

The KCM series features a compact radial lead design and is available in sizes ranging from 5mm to 18mm in diameter. This ultra-miniaturized design offers significant advantages in space-constrained applications, such as high-density circuit boards and portable electronic devices.

Optimized material selection and manufacturing processes utilize high-purity aluminum foil and a specialized electrolyte formulation. This combination not only improves the capacitor's electrical performance but also significantly extends its lifespan. Specialized sealing technology prevents electrolyte leakage or premature drying, ensuring long-term stability.

The KCM series products also performed exceptionally well in durability testing. After high-temperature and high-humidity testing (105°C for 1000 hours), the product's capacity change remained within ±20% of its initial value, and its loss tangent remained below 200% of the specified value. These data fully demonstrate the product's reliability in harsh environments.

Wide Application Scenarios

The technical characteristics of the KCM series aluminum electrolytic capacitors make them valuable in a variety of applications.

In the new energy vehicle sector, the KCM series can be used in key components such as onboard chargers, motor controllers, and DC-DC converters. Its high withstand voltage and high-temperature stability meet the stringent reliability requirements of automotive electronics, particularly in high-temperature environments such as underhoods.

In industrial automation, the KCM series is suitable for equipment such as inverters, servo drives, and industrial power supplies. Its lightning surge protection provides additional protection for outdoor industrial equipment, while its long life reduces maintenance and lowers overall operating costs.

In the communications equipment sector, applications such as 5G base stations and server power supplies place extremely high demands on capacitor performance and reliability. The KCM series' high-frequency, low-impedance characteristics enable it to effectively filter high-frequency noise, ensuring stable operation of communications equipment.

The KCM series also demonstrates promising application prospects in new energy and power electronics applications, such as smart grids, photovoltaic inverters, and uninterruptible power supplies (UPS). Its high withstand voltage and large capacity effectively smooth voltage fluctuations and improve energy conversion efficiency.

Engineering Design Value

Choosing the KCM series aluminum electrolytic capacitors is more than just selecting an electronic component; it's choosing a reliable solution.

From an engineering design perspective, the KCM series' long lifespan can significantly extend the lifespan of end products, reducing the frequency of repairs and replacements. For industrial equipment and infrastructure products, this translates to lower lifecycle costs and higher operational efficiency.

The product's consistency and stability provide designers with greater design margin. Engineers can leverage the KCM series' reliable performance to optimize system design and improve overall performance. For example, in power supply design, the KCM series' low ESR characteristics can be leveraged to achieve higher-efficiency power conversion.

From a supply chain perspective, YMIN's comprehensive product line and selection of specifications provide designers with ample flexibility. A variety of sizes and capacitances meet diverse design requirements, while unified quality standards ensure product consistency.

Conclusion

The KCM series of aluminum electrolytic capacitors represents the pinnacle of modern aluminum electrolytic capacitor technology. Their excellent temperature characteristics, withstand voltage, and long life make them an ideal choice for demanding electronic devices. As electronic devices increasingly pursue high reliability, long life, and miniaturization, the value of the KCM series will be increasingly recognized.

Whether in new energy vehicles, industrial automation, or communications infrastructure, the KCM series provides reliable "energy protection" for electronic systems, ensuring stable operation in a variety of harsh environments. With continuous technological advancements and increasingly diverse application requirements, the KCM series of aluminum electrolytic capacitors will continue to provide solid support for the development of the electronics industry.

| Products Number | Operating temperature (℃) | Voltage(V.DC) | Capacitance(uF) | Diameter(mm) | Length(mm) | Leakage current (uA) | Rated ripple current [mA/r.m.s] | ESR/ Impedance [Ωmax] | Life (hrs) | Certification |

| KCMD1202G150MF | -40~105 | 400 | 15 | 8 | 12 | 130 | 281 | - | 3000 | —— |

| KCMD1402G180MF | -40~105 | 400 | 18 | 8 | 14 | 154 | 314 | - | 3000 | —— |

| KCMD1602G220MF | -40~105 | 400 | 22 | 8 | 16 | 186 | 406 | - | 3000 | —— |

| KCMD1802G270MF | -40~105 | 400 | 27 | 8 | 18 | 226 | 355 | - | 3000 | —— |

| KCMD2502G330MF | -40~105 | 400 | 33 | 8 | 25 | 274 | 389 | - | 3000 | —— |

| KCME1602G330MF | -40~105 | 400 | 33 | 10 | 16 | 274 | 475 | - | 3000 | —— |

| KCME1902G390MF | -40~105 | 400 | 39 | 10 | 19 | 322 | 550 | - | 3000 | —— |

| KCML1602G390MF | -40~105 | 400 | 39 | 12.5 | 16 | 322 | 562 | - | 3000 | —— |

| KCMS1702G470MF | -40~105 | 400 | 47 | 13 | 17 | 386 | 668 | - | 3000 | —— |

| KCMS1902G560MF | -40~105 | 400 | 56 | 13 | 19 | 458 | 825 | - | 3000 | —— |

| KCMD3002G390MF | -40~105 | 400 | 39 | 8 | 30 | 244 | 440 | 2.5 | 3000 | - |

| KCMD3002G470MF | -40~105 | 400 | 47 | 8 | 30 | 292 | 440 | 2.5 | 3000 | - |

| KCMD3502G470MF | -40~105 | 400 | 47 | 8 | 35 | 292 | 450 | 2.5 | 3000 | - |

| KCMD3502G560MF | -40~105 | 400 | 56 | 8 | 35 | 346 | 600 | 1.85 | 3000 | - |

| KCMD4002G560MF | -40~105 | 400 | 56 | 8 | 40 | 346 | 500 | 2.5 | 3000 | - |

| KCME3002G680MF | -40~105 | 400 | 68 | 10 | 30 | 418 | 750 | 1.55 | 3000 | - |

| KCMI1602G680MF | -40~105 | 400 | 68 | 16 | 16 | 418 | 600 | 1.58 | 3000 | - |

| KCME3502G820MF | -40~105 | 400 | 82 | 10 | 35 | 502 | 860 | 1.4 | 3000 | - |

| KCMI1802G820MF | -40~105 | 400 | 82 | 16 | 18 | 502 | 950 | 1.4 | 3000 | - |

| KCMI2002G820MF | -40~105 | 400 | 82 | 16 | 20 | 502 | 1000 | 1.4 | 3000 | - |

| KCMJ1602G820MF | -40~105 | 400 | 82 | 18 | 16 | 502 | 970 | 1.4 | 3000 | - |

| KCME4002G101MF | -40~105 | 400 | 100 | 10 | 40 | 610 | 700 | 1.98 | 3000 | - |

| KCML3002G101MF | -40~105 | 400 | 100 | 12.5 | 30 | 610 | 1000 | 1.4 | 3000 | - |

| KCMI2002G101MF | -40~105 | 400 | 100 | 16 | 20 | 610 | 1050 | 1.35 | 3000 | - |

| KCMJ1802G101MF | -40~105 | 400 | 100 | 18 | 18 | 610 | 1080 | 1.35 | 3000 | - |

| KCME5002G121MF | -40~105 | 400 | 120 | 10 | 50 | 730 | 1200 | 1.25 | 3000 | - |

| KCML3502G121MF | -40~105 | 400 | 120 | 12.5 | 35 | 730 | 1150 | 1.25 | 3000 | - |

| KCMS3002G121MF | -40~105 | 400 | 120 | 13 | 30 | 730 | 1250 | 1.25 | 3000 | - |

| KCMI2502G121MF | -40~105 | 400 | 120 | 16 | 25 | 730 | 1200 | 1.2 | 3000 | - |

| KCMJ2002G121MF | -40~105 | 400 | 120 | 18 | 20 | 730 | 1150 | 1.08 | 3000 | - |

| KCMI2502G151MF | -40~105 | 400 | 150 | 16 | 25 | 910 | 1000 | 1 | 3000 | - |

| KCMI3002G151MF | -40~105 | 400 | 150 | 16 | 30 | 910 | 1450 | 1.15 | 3000 | - |

| KCMJ2502G151MF | -40~105 | 400 | 150 | 18 | 25 | 910 | 1450 | 1.15 | 3000 | - |

| KCMJ2502G181MF | -40~105 | 400 | 180 | 18 | 25 | 1090 | 1350 | 0.9 | 3000 | - |

| KCM E4002W680MF | -40~105 | 450 | 68 | 10 | 40 | 469 | 890 | 1.6 | 3000 | - |

| KCMJ1602W680MF | -40~105 | 450 | 68 | 18 | 16 | 469 | 870 | 1.6 | 3000 | - |

| KCMI2002W820MF | -40~105 | 450 | 82 | 16 | 20 | 563.5 | 1000 | 1.45 | 3000 | - |

| KCMJ2002W101MF | -40~105 | 450 | 100 | 18 | 20 | 685 | 1180 | 1.38 | 3000 | - |

| KCMS5002W151MF | -40~105 | 450 | 150 | 13 | 50 | 1022.5 | 1450 | 1.05 | 3000 | - |